One of the main hurdles to the acceptance of plant-based meat alternatives is their dry and astringent texture when consumed.

A team of scientists, led by Professor Anwesha Sarkar at the University of Leeds, is revolutionizing the experience of plant proteins by transforming them from a gloopy and dry substance into one that is juicy and fatty, using only water.

Plant protein microgels

To achieve this breakthrough, the scientists developed plant protein microgels through a process called microgeletion.

Initially, plant proteins, which are dry and rough in texture, are immersed in water and subjected to heat. This alters the structure of the protein molecules, causing them to form a connected network or gel that traps water around the plant proteins.

The gel is then homogenized, breaking the protein network into tiny particles that are not visible to the naked eye. When subjected to pressure, such as when eaten, the microgels release water, creating a lubricating texture similar to single cream.

Professor Sarkar explains, “What we have done is convert the dry plant protein into a hydrated one, using the plant protein to form a spider-like web that holds the water around the plant protein.”

“This provides the much-needed hydration and juicy sensation in the mouth.”

“Plant-based protein microgels can be created without the use of any additional chemicals or agents, using a widely available technique currently used in the food industry. The key ingredient is water.”

Revitalizing consumer interest

The research team, whose findings are published in the journal Nature Communications, believes that the dryness of plant proteins has been a significant barrier to consumer acceptance.

With this breakthrough, they hope to generate renewed interest in plant-based proteins, encouraging people to reduce their consumption of animal products for protein intake, a necessary step in achieving global climate change targets.

Over half of the 18 billion metric tons of carbon dioxide equivalents produced annually from food production comes from the rearing and processing of animal products.

The researchers believe that protein microgels offer a unique opportunity to design the next generation of healthy, appetizing, and sustainable foods.

Eureka moment

Throughout their investigation, the team mathematically modeled the behavior of plant protein microgels and were confident in their approach.

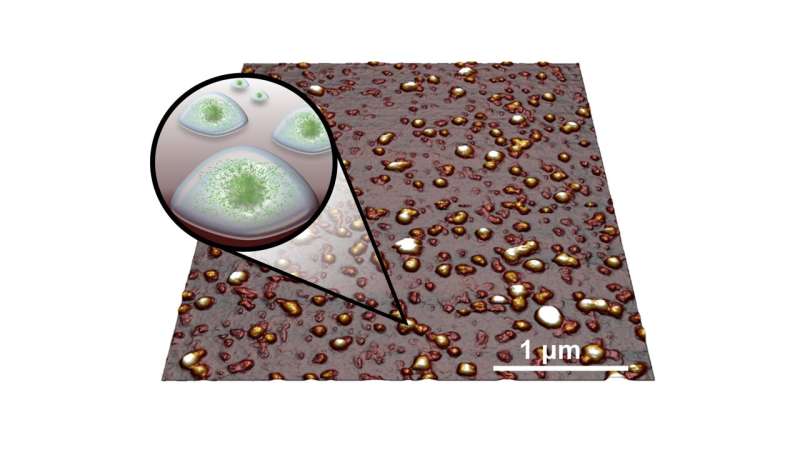

Their proof came in the form of visualizations produced by an atomic force microscope in the Faculty of Engineering and Physical Sciences at Leeds. Atomic force microscopy involves a probe scanning the surface of a molecule to visualize its shape.

The resulting images provided proof of concept.

Professor Sarkar exclaimed, “Seeing the images from the atomic force microscope was an incredibly exciting moment for us. The visualizations revealed that the protein microgels were nearly spherical and not clumping together. We could see individually spaced plant protein microgels.

“Our theoretical studies had predicted this outcome, but there is nothing quite like seeing it for real.”

Dr. Mel Holmes, Associate Professor in the School of Food Science and Nutrition at Leeds and one of the paper’s authors, stated, “This study demonstrates the ingenuity and depth of science involved in modern food technology, from the chemistry of proteins and the sensory aspects of food in the mouth to our understanding of tribology—the interaction between materials and sensory cells in the mouth.”

“Addressing the significant questions in food science requires interdisciplinary collaboration.”

Broader applications of plant protein microgels

Due to the lubricating properties of the microgels, similar to that of single cream, they could be utilized for other purposes in the food processing industry, such as replacing removed fat in the development of healthier alternatives.

Ben Kew, a doctoral student in the School of Food Science and Nutrition at Leeds and the lead researcher of the project, stated, “This is a remarkable finding. It is striking that without adding any fat, the microgels exhibit the lubricity of a 20% fat emulsion, which has not been reported before.”

“Our experimental data, supported by theoretical analyses, also suggest that these plant protein microgels could be used in foods where fat needs to be removed to create healthier plant-based options for the next generation.”

More information:

Ben Kew et al, Transforming sustainable plant proteins into high-performance lubricating microgels, Nature Communications (2023). DOI: 10.1038/s41467-023-40414-7

Citation:

Making plant-based meat alternatives more palatable with protein microgels (2023, August 14)

retrieved 14 August 2023

from https://phys.org/news/202

Denial of responsibility! SamacharCentrl is an automatic aggregator of Global media. In each content, the hyperlink to the primary source is specified. All trademarks belong to their rightful owners, and all materials to their authors. For any complaint, please reach us at – [email protected]. We will take necessary action within 24 hours.

Shambhu Kumar is a science communicator, making complex scientific topics accessible to all. His articles explore breakthroughs in various scientific disciplines, from space exploration to cutting-edge research.

Denial of responsibility! Samachar Central is an automatic aggregator of Global media. In each content, the hyperlink to the primary source is specified. All trademarks belong to their rightful owners, and all materials to their authors. For any complaint, please reach us at – [email protected]. We will take necessary action within 24 hours.